Waste Water Treatment Plant Based on MBR Technology

3650000 INR/Unit

Product Details:

- Voltage 380V/415V, 3 Phase (50/60 Hz)

- Lead Time 2-8 weeks, depending on plant size

- Capacity 10 KLD to 500 KLD and above

- Function Biological and Membrane Filtration for Wastewater Purification

- Weight Varies as per plant design

- Color Blue, Green, Custom available

- Power 3-60 kW, depending on capacity

- Click to View more

X

Waste Water Treatment Plant Based on MBR Technology Price And Quantity

- 1 Unit

- 3650000 INR/Unit

Waste Water Treatment Plant Based on MBR Technology Product Specifications

- Custom as per plant size and flow rate

- Mild Steel, FRP, Stainless Steel

- Waste Water Treatment Plant Based on MBR Technology

- Customized, based on client requirements

- 0.1-0.2 m pore size

- Blue, Green, Custom available

- 3-60 kW, depending on capacity

- Municipal, Industrial, Commercial, Residential Waste Water Treatment

- 10 KLD to 500 KLD and above

- 2-8 weeks, depending on plant size

- 380V/415V, 3 Phase (50/60 Hz)

- Biological and Membrane Filtration for Wastewater Purification

- Varies as per plant design

Waste Water Treatment Plant Based on MBR Technology Trade Information

- 1 Unit Per Month

- 1 Week

Product Description

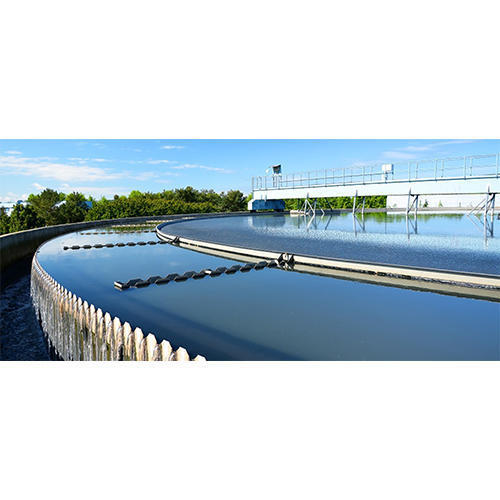

We are nationally renowned as the leading supplier of a wide range of Waste Water Treatment Plant Based on MBR Technology. It is employed to handle industrial wastewater released from manufacturing facilities. Even if the water is treated with dangerous chemicals, the plant ensures all waste is removed before discharging it into the environment. It helps preserve the ecological balance by serving as a resource for the ecosystem. This Waste Water Treatment Plant Based on MBR Technology is configured according to all relevant quality standards. Even in the most humid climates, the plant exhibits impressive resistance to corrosion. With the aid of forward-looking technology and top-quality materials, it is equipped for the future. Its options are numerous, so it is accessible to clients in varied feature sets to help satisfy all of their needs efficiently.

Waste Water Treatment Plant Based on MBR Technology Details:

- Product Details : MBR Waste Water Treatment Plant

- Minimum Order Quantity : 1 Piece

- Application : Wastewater Treatment

- Plant Type : Wastewater Treatment Plant, Drinking Water Treatment Plant, Effluent Treatment Plant, Sewage Treatment Plant

- Capacity : 1-1000 m3 / d

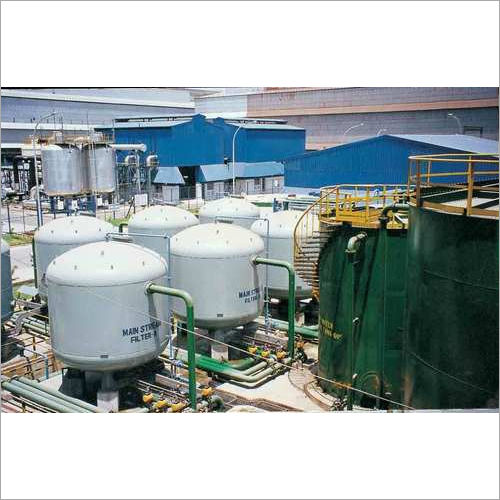

- Treatment Technique : Fluidized Aerated Reactor, Clarifier, Bio Tower, Mixed Bed Bio Reactor

- Capacity Inlet Flow Rate (cubic meter/hour) : 100 m3/hour, 5000 m3/hour, 1000 m3/hour, 500 m3/hour ,10000 m3/hour, 2000 m3/hour

- Automation Grade : Manual, Automatic, Semi-Automatic

- Installation Type : Complete Civil work with Installation,Containerized Plug and Play, Prefabricated

- Material : Carbon Steel

- Water Source : Commercial Waste Water,Industrial Effluent, River Water, Borewell Water, Municipal Sewage, Industrial Wastewater

Advanced MBR Technology for Superior Wastewater Purity

Membrane Bio Reactor (MBR) technology integrates biological treatment with membrane filtration, achieving exceptional removal of contaminants. With hollow fiber or flat sheet membranes of 0.1-0.2 m pore size, the plant ensures consistently clear and safe output. This technology is especially effective for demanding municipal and industrial settings, delivering effluent that surpasses strict regulatory standards.

Flexible Installation and Operational Ease

Our wastewater treatment systems are engineered for versatile deploymentoffered as skid-mounted, containerized, or constructed on-site based on your space and operational needs. Semi-automatic and fully automatic options, paired with PLC-based control panels and user-friendly HMIs, make plant operation intuitive, reliable, and adaptable to evolving requirements.

Customizable Capacities and Energy Efficiency

Designed with your volume handling in mind, this plant accommodates flows from 10 KLD up to 500 KLD or more and is optimized for low power consumption (3-60 kW). Energy-efficient air blowers and robust material selections (Mild Steel, FRP, Stainless Steel) ensure minimal running costs while maintaining high performance through a wide operating temperature range (5C45C).

FAQs of Waste Water Treatment Plant Based on MBR Technology:

Q: How does the MBR technology improve wastewater treatment efficiency compared to conventional methods?

A: MBR technology combines biological degradation and membrane filtration, allowing effective removal of suspended solids and organic contaminants. The membranes (hollow fiber or flat sheet, 0.1-0.2 m) act as a physical barrier to particles and microorganisms, resulting in treated water with BOD < 10 mg/L and SS < 10 mg/L. This outperforms traditional methods, especially in challenging applications.Q: What types of wastewater sources can be processed by this plant?

A: The plant is engineered to handle a variety of wastewater sources, including domestic sewage, greywater, and diverse industrial effluents. Its adaptable design ensures reliable performance across municipal, residential, commercial, and industrial applications, meeting regulatory discharge standards consistently.Q: When is a semi-automatic or automatic system recommended for use?

A: Semi-automatic configurations suit facilities with moderate technical oversight, where routine manual intervention is expected. Automatic systems, equipped with PLC-based control panels and HMI, are ideal for larger-scale or critical operations where minimal manual input and consistent, precise control are essential.Q: Where can this wastewater treatment plant be installed?

A: Installation possibilities include on-site construction, skid-mounted units, or fully containerized systems, offering maximum flexibility for urban, rural, and remote locations. The modular design enables rapid deployment in new or existing facilities, tailored to specific site dimensions and operational constraints.Q: What is the process flow in an MBR-based treatment plant?

A: The process begins with biological degradation of organic matter, followed by membrane filtration where ultrafine membranes separate solid particulates and microbes. Energy-efficient air blowers maintain optimal oxygenation, and a PLC-based control system ensures smooth, automated operation throughout the treatment stages.Q: How does the plant benefit end users in terms of operational costs and compliance?

A: The systems energy-efficient components and automation reduce operational expenses. With reliable achievement of BOD and SS targets, users remain in compliance with PCB/CPCB norms, avoiding penalties and supporting environmental stewardship, all while enjoying long-term cost savings and reduced manual oversight.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wastewater Treatment Plants' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS