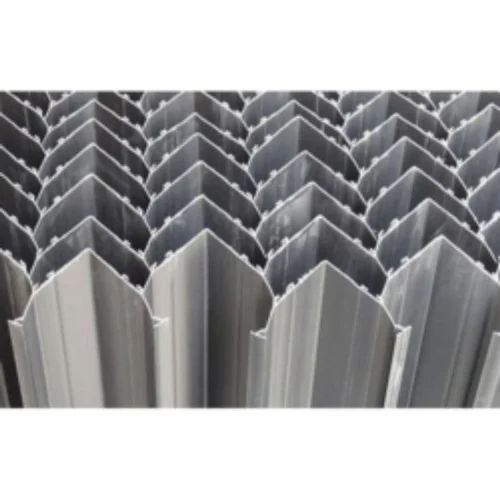

Industrial RO Membranes

Product Details:

- Efficiency (%) 98-99%

- Pump Type High Pressure Pump

- Noise Level <65 dB

- Water Out Conductivity <10 S/cm

- Technology Reverse Osmosis

- Usage & Applications Industrial Water Treatment, Boiler Feed, Food & Beverage Processing

- Recycle Rate Up to 90%

- Click to View more

X

Industrial RO Membranes Price And Quantity

Industrial RO Membranes Product Specifications

- Automatic

- Skid Mounted / Modular

- Industrial RO Membranes

- 1.5-5 kW

- Spiral Wound

- 220-240V

- 250-8000 GPD

- 2-11

- High Flow, Salt Rejection, Low Fouling

- Custom per system

- 50/60 Hz

- Up to 2000 S/cm

- Polyamide Composite

- High Pressure Pump

- Electric Motor

- <65 dB

- 98-99%

- <10 S/cm

- 200 LPH - 10,000 LPH

- Ground Water / Tap Water

- Reverse Osmosis

- Electric

- Up to 90%

- 99%

- Industrial Water Treatment, Boiler Feed, Food & Beverage Processing

Product Description

Experience highly recommended performance with our Industrial RO Membranes, now offered at a reduced price. Featuring eminent thin-film composite technology, these membranes assure optimum water purity-boasting a monumental >99% salt rejection rate and efficient recovery rates between 45-65%. Designed for durability, each membrane accommodates operating pressures from 150 to 600 psi and withstands feed water temps up to 45C. Highlighted by versatile cleaning compatibility, low fouling, and robust ABS/polypropylene end caps, they deliver outstanding reliability. Ideal for industrial water treatment, boiler feed, and food & beverage processing, our membranes promise long-term service with a lifespan of 2-4 years, ensuring a wise investment in every high-flow usage scenario.

Versatile Features & Industrial Advantages

Industrial RO Membranes combine high-efficiency filtration with exceptional durability, suitable for complex industrial tasks. Featuring low fouling, high flow, and a wide pH range (2-11), they support diverse applications from water treatment and boiler feed to food and beverage processing. The automatic, modular design ensures seamless installation and flexible operation, while spiral-wound, polyamide construction optimizes recovery and energy efficiency. Enjoy reduced maintenance and long-term operational stability, making these membranes a highlighted choice for demanding industrial environments.

Certifications, Sampling & Global Markets

Our membranes come with internationally recognized certifications for quality assurance and compliance. Samples are available for evaluation prior to bulk order, ensuring buyers can check list price versus product satisfaction. With quick dispatch and reliable goods transport, we efficiently serve main export markets in Asia, Africa, the Middle East, and beyond. Customers benefit from prompt delivery, responsive service, and a transparent quotation process-making us a preferred supplier, manufacturer, and exporter from India.

Versatile Features & Industrial Advantages

Industrial RO Membranes combine high-efficiency filtration with exceptional durability, suitable for complex industrial tasks. Featuring low fouling, high flow, and a wide pH range (2-11), they support diverse applications from water treatment and boiler feed to food and beverage processing. The automatic, modular design ensures seamless installation and flexible operation, while spiral-wound, polyamide construction optimizes recovery and energy efficiency. Enjoy reduced maintenance and long-term operational stability, making these membranes a highlighted choice for demanding industrial environments.

Certifications, Sampling & Global Markets

Our membranes come with internationally recognized certifications for quality assurance and compliance. Samples are available for evaluation prior to bulk order, ensuring buyers can check list price versus product satisfaction. With quick dispatch and reliable goods transport, we efficiently serve main export markets in Asia, Africa, the Middle East, and beyond. Customers benefit from prompt delivery, responsive service, and a transparent quotation process-making us a preferred supplier, manufacturer, and exporter from India.

FAQ's of Industrial RO Membranes:

Q: How do Industrial RO Membranes improve water quality in industrial operations?

A: They achieve over 99% salt rejection and filter impurities, ensuring highly purified water output for use in processes like boiler feed and beverage manufacturing.Q: What are the primary benefits of using thin-film composite membranes in your system?

A: Thin-film composite membranes offer high salt rejection, low fouling, robust chemical compatibility, and durability, making them optimum for industrial-scale water treatment.Q: Where can these membranes be installed and what is the installation process?

A: They are suited for skid-mounted or modular setups in diverse industrial facilities. Installation involves mounting the membrane in an appropriate housing and connecting it to the existing RO system.Q: What cleaning methods are compatible with these membranes?

A: Both acid and alkaline cleaning agents can be used for maintenance, enhancing membrane lifespan and consistent performance.Q: When is it advisable to replace the Industrial RO Membranes?

A: Membranes typically perform efficiently for 2-4 years; replacement is recommended when salt rejection or flow rate drops significantly despite proper maintenance.Q: How quickly can Industrial RO Membranes be dispatched after ordering?

A: Thanks to streamlined logistics and robust goods transport capabilities, quick dispatch is possible, especially for standard sizes and common configurations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Water Treatment Components' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS