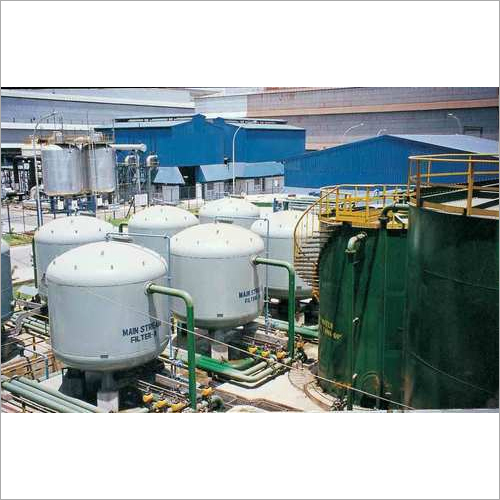

Zero Liquid Discharge System

2850000 INR/Unit

Product Details:

- Membrane Quantity As per design (generally 12-36 units)

- Product Type Zero Liquid Discharge System

- Application Industrial Wastewater Treatment, Effluent Management

- Power 50-200 kW (Depending on capacity)

- Color Grey / Blue / Custom

- Capacity 5 KLD to 1000 KLD (Kilo Liters per Day)

- Material Mild Steel (MS), Stainless Steel (SS)

- Click to View more

X

Zero Liquid Discharge System Price And Quantity

- 2850000 INR/Unit

- 1 Unit

Zero Liquid Discharge System Product Specifications

- 8 inch / 4 inch (Standard options)

- Customized as per requirement

- 380-440 V, 3 Phase, 50/60 Hz

- Complete Recovery of Water & Salt Separation from Effluent

- 45-75 days

- Depends on plant capacity (typically 2-8 tons)

- 5 KLD to 1000 KLD (Kilo Liters per Day)

- Mild Steel (MS), Stainless Steel (SS)

- Grey / Blue / Custom

- Industrial Wastewater Treatment, Effluent Management

- 50-200 kW (Depending on capacity)

- As per design (generally 12-36 units)

- Zero Liquid Discharge System

Zero Liquid Discharge System Trade Information

- 1 Unit Per Month

- 1 Week

- All India

Product Description

Zero Liquid Discharge System lies in industrial waste-water treatment procedures developed to entirely deplete all liquid emission from the industrial installation. A zero liquid discharge is an activity that is advantageous to municipal and industrial governing bodies as well as to the environment because it is cost efficient and needs and no liquid effluent. ZLD systems utilize the most precocious waste-water treatment applications to sublimate and recycle nearly all of the waste-water bring forth.

Proffered Zero Liquid Discharge System is highly beneficial for industrial as well as municipal organizations. Equally helpful for the environment, the system saves money without the residual of effluent, or discharge. The technology of the plant run into discharge and water reuse requirements. This advanced technique includes reverse osmosis, ultra-filtration, crystallization and fractional electrode-ionization.

Zero liquid discharge technologies to assist industry meet discharge and water reuse demands, enabling enterprise to:

- Run into demanding cooling tower blow-down and flue gas desulfurization (FGD) discharge standards.

- Recover and treat precious products from waste streams.

- Finer management in process water.

Applications : Zero Liquid Discharge Solutions- needs and usages can be attained with multiple activities of the following:

- Reverse Osmosis System

- Ultra Filtration System

- Evaporation System

- Sea Water RO System for High TDS

ZLD Crystallizers Features:

- Our patented produced water evaporators are effectual in treating SAGD made water and once-through steam generator (OTSG) blow-down.

- Skid-mounted, totally packaged systems, which include auxiliary instrumentality and controls for simplicity of installation.

- Configured to retrieve specific waste stream salts for precious product recovery.

- Uncomplicated color graphic controls and an automated wash system to insure simplicity of operation.

- Minimum energy intake with mechanical vapor re-compression

- Steam vapor recycling espouses (MVR) technology.

Leveraging our rich industry experience, we bring forth Zero Water Discharge services to our revered customers. These services are aimed at devising cost effective methods for the effective recycle of industrial waste water. Our professionals suggest cost effective methods to enable the same and oversee the implementation process till the end. Customers are reasonably charged for these services.

Features:

- Advantages: Zero Discharge

- Low Investment

- Low Running Costs

- Automatic Control

- Application: Factory , Airport etc.

Technical Specification

| Minimum Order Quantity | 1 Unit |

| Application | Zero Liquid Discharge wastewater |

| Installation Service | Yes |

| Automatic Grade | Manual,Semi-Automatic,Automatic |

| Water Source | Municipal Sewage,Industrial Effluent,Commercial Waste Water |

| Treatment Stages | Preliminary Treatment,Tertiary Treatment,Disinfection,Secondary Treatment,Primary Treatment |

| Installation Type | Completes Civil work with Installation,Prefabricated,Containerized Plug & Play |

| Type | Disc-tube Module Components |

| Features | Anti-fouling and low cost |

Advanced Automation for Reliable Operation

Zero Liquid Discharge System comes with automatic and semi-automatic modes, powered by a robust PLC-based control panel. This ensures consistent system performance, minimizes manual intervention, and enhances safety. Operators can monitor and manage the complete process efficiently, adapting to variable feed water qualities and operational demands.

Superior Water Recovery & Salt Management

With water recovery rates up to 95%, the ZLD System significantly reduces freshwater consumption and effluent discharge. Integrated salt handling and advanced evaporation technologies such as MEE and ATFD guarantee effective separation and environmental compliance, facilitating responsible industrial effluent management and resource reuse.

Customizable Design For Diverse Industrial Needs

Tailored to meet specific requirements, the ZLD System offers flexible dimensions, varying membrane configurations, and customizable capacities from 5 to 1000 KLD. Constructed from durable mild steel or stainless steel, it is suitable for various industrial settings, from effluent management to complete wastewater treatment.

FAQs of Zero Liquid Discharge System:

Q: How does the Zero Liquid Discharge System achieve up to 95% water recovery from industrial wastewater?

A: The system utilizes advanced multi-effect evaporators (MEE), ATFD technology, and carefully designed membrane arrays to maximize water recovery. This process separates salts and contaminants, allowing up to 95% of input water to be reclaimed for reuse in industrial operations.Q: What types of feed water can the ZLD System handle, and is pretreatment always necessary?

A: The ZLD System accommodates feed water temperatures from 5C to 45C and total dissolved solids (TDS) up to 80,000 ppm. Pretreatment is required to ensure optimal performance and protect system components, with specific processes determined by the initial water quality.Q: Where can the ZLD System be installed, and do you provide installation services?

A: Our ZLD System is suitable for various industrial settings requiring effluent management or wastewater treatment. Full installation services are available, and dimensions, weight, and configurations are customized to match your sites requirements.Q: What is the process for salt separation and disposal in this ZLD System?

A: The integrated salt handling system collects separated salts after water recovery. These are processed using the combined multi-effect evaporator and ATFD setups, ensuring environmentally compliant disposal while meeting ZLD regulatory guidelines.Q: What are the benefits of using a PLC-based control panel in ZLD operations?

A: A PLC-based control panel enables precise automation, real-time monitoring, and flexible control over system parameters. It increases reliability, reduces operator workload, and optimizes overall plant performance for both automatic and semi-automatic models.Q: When can I expect delivery and installation of the ZLD plant after placing an order?

A: Lead time for delivery and installation ranges from 45 to 75 days, depending on plant capacity, customization, and project complexity. Detailed timelines are provided after order confirmation.Q: What capacities and power requirements are available for the ZLD System?

A: Our systems support capacities from 5 KLD to 1000 KLD, with power consumption ranging between 50 and 200 kW, tailored to the plants size and throughput needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wastewater Treatment Plants' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS