Hydraulic Filter Press for Effluent Treatment Plants

90000-1000000 INR/Set

Product Details:

- Application Effluent Treatment, Chemical, Mining, Food & Beverage

- Installation Type Skid Mounted / Horizontal

- Material Mild Steel Frame / Polypropylene Plates

- Membrane Size 610 mm x 610 mm / 800 mm x 800 mm

- Treatment Technique Hydraulic Pressure Filtration

- Water Source Effluent / Industrial Wastewater

- Product Type Effluent Treatment Filter Press

- Click to View more

X

Hydraulic Filter Press for Effluent Treatment Plants Price And Quantity

- 90000-1000000 INR/Set

- 90000.00 - 100000.00 INR/Set

- 01 Set

Hydraulic Filter Press for Effluent Treatment Plants Product Specifications

- Hydraulic Pressure Filtration

- Effluent Treatment, Chemical, Mining, Food & Beverage

- Electric

- 3700 mm x 1200 mm x 1400 mm (Standard Model)

- Plate and Frame Filter Press

- Skid Mounted / Horizontal

- Effluent / Industrial Wastewater

- Mild Steel Frame / Polypropylene Plates

- Blue & Yellow (Standard)

- 610 mm x 610 mm / 800 mm x 800 mm

- Effluent Treatment Filter Press

Hydraulic Filter Press for Effluent Treatment Plants Trade Information

- All India

Product Description

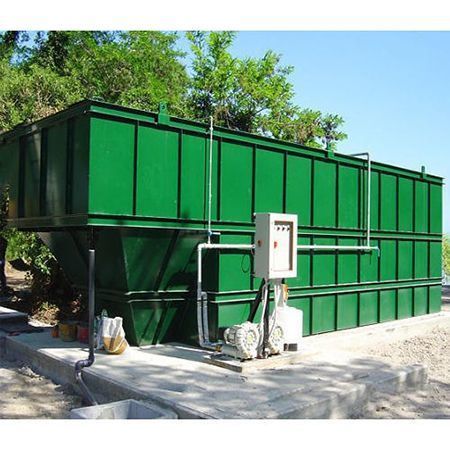

Aided by innovative machinery and a dedicated workforce, we are able to manufacture, supply and trade Hydraulic Filter Press. These products are used at various industries and factories for recycling waste water. Tested as per the industrial standards, these products provide exceptional performance, have longer service life and require very less maintenance. In order to meet the requirements of the clients, we can alter the shape and size of these products. Hydraulic Filter Press is available with us at industry leading rates.

Specifications of Filter Presses

-

Available in Squares PP470 x 470 - 600 x 600 - 800 x 800 - 915 x 915 - 1000 x 1000 - 1200 x 1200

-

Available in Round PP600mm and 800mm

-

Available in stainless steel, C.I. and C.S

Used For

-

Solid separation

-

Liquid separation

Offers Various Forms

- Manual Closing

- Ratchet Gear Type

- Semi Hydraulic

- Auto Hydraulic

Technical Specification

| Minimum Order Quantity | 1 Unit |

| Filter Area | 300-400 m2,400-500 m2,<100 m2,200-300 m2,<100 m2,100-200 m2 |

| Automation Grade | Semi-Automatic,Manual,Automatic |

| No Of Plates | 40-50,30-40,20-30,10-20,>50 |

Advanced Filtration Technology

The hydraulic filter press employs plate and frame filtration to efficiently process effluent and industrial wastewater. With hydraulically applied pressure, the solid-liquid separation achieves high clarity filtrate. The polypropylene plates ensure chemical resistance, suitable for various industries.

Flexible Installation and Design

Engineered with a compact, skid-mounted and horizontal installation, this filter press is ideal for varying industrial settings. Its standard model dimensions (3700 mm x 1200 mm x 1400 mm) allow easy integration into existing facilities, saving space without sacrificing performance.

Versatility Across Industries

Designed for effluent treatment, chemical processing, mining, and food & beverage sectors, the filter press adapts to diverse operational requirements. Its durable mild steel frame and electric operation ensure consistent performance, making it a valuable addition to any industrial filtration system.

FAQs of Hydraulic Filter Press for Effluent Treatment Plants:

Q: How does the hydraulic filter press operate in effluent treatment plants?

A: The filter press utilizes hydraulic force to press plates together, forming chambers where effluent is pumped in. Under pressure, water passes through filtration media, capturing solids on the plates, thus separating contaminants from the liquid for safer disposal or reuse.Q: What are the benefits of using a plate and frame filter press for industrial wastewater?

A: Plate and frame filter presses deliver efficient solid-liquid separation, handle high sludge volumes, and produce dry filter cakes. They reduce disposal costs, enhance water recovery, and are designed for easy maintenance and durability in demanding industrial environments.Q: When should the hydraulic filter press be operated during the treatment process?

A: The filter press is typically used after primary and secondary treatment phases, once solids need to be separated from liquid effluents. Its operation is crucial at the dewatering stage to minimize waste volume and manage sludge effectively.Q: Where can the hydraulic filter press be installed in an effluent treatment plant?

A: Thanks to its skid-mounted and horizontal design, the filter press can be conveniently installed beside sedimentation tanks, sludge handling areas, or within compact treatment units. Its flexible footprint supports a variety of industrial plant layouts.Q: What industries benefit most from this hydraulic filter press technology?

A: Industries such as chemical, mining, food & beverage, and general effluent treatment benefit greatly. Its robust materials and adaptable design allow it to handle diverse waste streams, high solids loading, and varied operational requirements.Q: How should the hydraulic filter press be maintained for long service life?

A: Routine maintenance involves checking hydraulic system pressure, inspecting plates for wear or buildup, cleaning filter cloths, and ensuring seals are intact. Regular upkeep maximizes equipment efficiency and minimizes unexpected downtime.Q: What size and material options are available for the plates and frame?

A: Standard models come with plate sizes of 610 mm x 610 mm and 800 mm x 800 mm. The frame is constructed from mild steel for strength, while the plates are made of polypropylene to resist chemicals and facilitate easy cleaning.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Effluent Treatment Plant' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free