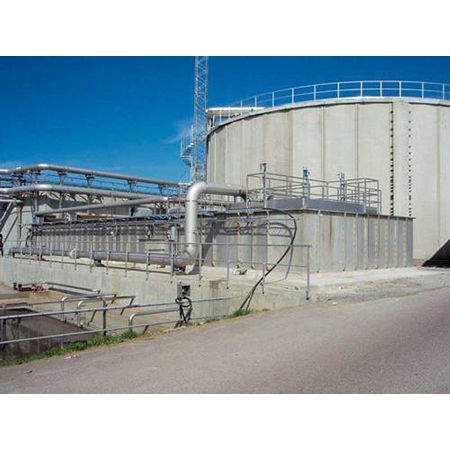

Effluent Treatment Plant for Textile Dyeing Industry

350000.0 INR/Unit

Product Details:

- Material Mild Steel

- Application Industrial

- Technology Mixed Bed Bio Reactor

- Power Source Electric

- Warranty Yes

- Click to View more

X

Effluent Treatment Plant for Textile Dyeing Industry Price And Quantity

- 350000.0 INR/Unit

- 1 Unit

Effluent Treatment Plant for Textile Dyeing Industry Product Specifications

- Mild Steel

- Mixed Bed Bio Reactor

- Electric

- Yes

- Industrial

Effluent Treatment Plant for Textile Dyeing Industry Trade Information

- 1 Unit Per Month

- 1 Week

Product Description

Effluent Treatment Plant for Textile Dyeing Industry Technical Details:

- Product Type: Effluent Treatment Plant

- Minimum Order Quantity : 1 Unit

- Treatment Stages : Primary Treatment,Disinfection,Secondary Treatment,Preliminary Treatment,Tertiary Treatment

- Impurities to be removed : Oil and Grease, Turbidity, pH, TDS, Colour, Dissolved Minerals

- Automation Grade : Semi-Automatic,Automatic

- Water Source : Municipal Sewage,Industrial Effluent, Industrial Wastewater,Commercial Waste Water

- Industry : Distillery,Slaughter House,Sugar Industry,Chemical/Petroleum Industry,Leather Industry,Pharmaceutical Industry,Paper Mills,Dairy Industry,Automobile

- Secondary Treatment Type : Fixed Film Bioreactor, Trickling Filters,Moving Bed Bioreactor (MBBR), Fluidized Aerated Reactor, Dissolved Air Floatation, Activated Sludge

Advanced Mixed Bed Bio Reactor Technology

The implementation of Mixed Bed Bio Reactor (MBBR) technology ensures that our ETP delivers highly effective biological treatment of complex textile effluents. This technology enhances the breakdown of pollutants through an optimized microbial process, enabling compliance with industry standards.

Durable Mild Steel Construction

Our Effluent Treatment Plants are fabricated using high-quality mild steel, providing longevity and resistance to industrial wear. This ensures minimal maintenance and reliable operation even in demanding textile dyeing environments.

Comprehensive Service & Support

We not only manufacture and export ETP systems but also offer expert installation, maintenance, and technical support throughout India. Our team ensures your plant achieves maximum purification efficiency, long-term reliability, and meets all environmental compliance requirements.

FAQs of Effluent Treatment Plant for Textile Dyeing Industry:

Q: How does the Mixed Bed Bio Reactor technology improve the effectiveness of the ETP in textile dyeing applications?

A: The Mixed Bed Bio Reactor (MBBR) technology enhances biological treatment by using vast surfaces for microorganisms to attach, rapidly breaking down organic and inorganic pollutants typical in textile dyeing wastewater. This results in higher removal efficiency and better compliance with discharge norms.Q: What materials are used to construct the Effluent Treatment Plant for textile industries, and why?

A: Our ETPs are primarily built from mild steel, chosen for its robust strength, corrosion resistance, and cost-effectiveness. This material withstands the challenging chemical environment found in textile wastewater processes, ensuring reliable, long-term performance.Q: When should a textile dyeing facility consider installing an ETP?

A: A textile dyeing facility should install an ETP before commencing operations or when expanding production to adhere to environmental regulations. Early installation helps maintain sustainable operations and avoid penalties for non-compliance with wastewater discharge standards.Q: Where can your Effluent Treatment Plant be supplied and installed in India?

A: We supply, install, and service our Effluent Treatment Plants at textile dyeing facilities across India. Whether in industrial clusters or remote locations, our team provides support to ensure optimal plant performance nationwide.Q: What is the general process flow of this Effluent Treatment Plant?

A: The ETP processes effluent through multiple stages: initial screening, primary and secondary biological treatment via MBBR, and final clarification before safe discharge or reuse. Each stage effectively removes contaminants, ensuring treated water meets stringent regulatory criteria.Q: In which ways does using an ETP benefit textile dyeing manufacturers?

A: Using our ETP enables manufacturers to minimize their environmental footprint, enhance compliance with pollution control laws, and safeguard public health. It ultimately strengthens brand reputation and supports long-term sustainable industrial growth.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Effluent Treatment Plant' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS