Waste Water Treatment Plant for Slaughter Houses

158000.00 INR/Unit

Product Details:

- Product Type Waste Water Treatment Plant for Slaughter Houses

- Membrane Size 0.1 micron

- Material Mild Steel, Stainless Steel

- Dimension (L*W*H) Customizable (as per site requirements)

- Power 15 kW

- Membrane Quantity Standard: 10 units (expandable as per capacity)

- Capacity 25 - 500 m/day

- Click to View more

X

Waste Water Treatment Plant for Slaughter Houses Price And Quantity

- 1 Unit

- 158000.00 INR/Unit

Waste Water Treatment Plant for Slaughter Houses Product Specifications

- Waste Water Treatment Plant for Slaughter Houses

- 0.1 micron

- 15 kW

- Customizable (as per site requirements)

- Mild Steel, Stainless Steel

- 30 - 45 days

- Green / Grey

- 380 V

- Effluent treatment, waste water purification, removal of organic load, COD & BOD reduction

- 2400 kg (approx)

- Standard: 10 units (expandable as per capacity)

- 25 - 500 m/day

- Slaughter houses, Meat processing units, Abattoirs

Waste Water Treatment Plant for Slaughter Houses Trade Information

- 1 Unit Per Week

- 1 Months

Product Description

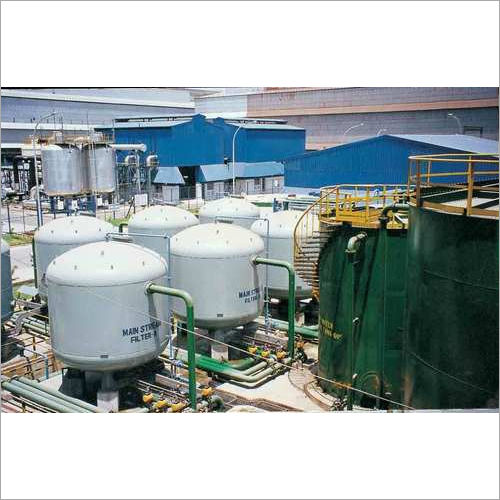

Waste Water Treatment Plant for Slaughter Houses Technical Details:- Water Source : Industrial Effluent, Municipal Sewage, Commercial Waste Water

- Treatment Technique : Mixed Bed Bio Reactor, Bio Tower, Fluidized Aerated Reactor, Clarifier

- Treatment Stages : Tertiary Treatment, Preliminary Treatment, Secondary Treatment, Disinfection, Primary Treatment

- Automatic Grade : Automatic

Specification

| Automatic Grade | Automatic |

| Usage/Application | 1-10000 M3/HR |

| Treatment Technique | Bio Tower,Mixed Bed Bio Reactor,Fluidized Aerated Reactor,Clarifier |

| Water Source | Industrial Effluent,Commercial Waste Water,Municipal Sewage |

| Treatment Stages | Secondary Treatment,Disinfection,Primary Treatment,Tertiary Treatment,Preliminary Treatment |

| Delivery Location | World Wide |

Comprehensive Effluent Purification

This wastewater treatment solution is tailored for the unique demands of slaughterhouses and meat processing plants. With multiple pretreatment stages and fine membrane filtration, the plant effectively removes organic contaminants, oil, and grease, ensuring a clean, compliant effluent stream.

Smart Automation & Flexible Operation

Equipped with a PLC-based control system, operators benefit from automated management, real-time monitoring, and data-driven efficiency. Its variable flow rate and temperature tolerance make it suitable for a wide range of operational conditions and site sizes, while modular, skid-mounted design allows for quick installation and easy scalability.

FAQs of Waste Water Treatment Plant for Slaughter Houses:

Q: How does the diffused air aeration system work in this wastewater treatment plant?

A: The diffused air aeration system introduces fine air bubbles into the wastewater using special diffusers, which enhances oxygen transfer and promotes microbial activity for the efficient breakdown of organic pollutants.Q: What process is followed for pretreatment in slaughterhouse wastewater?

A: The plant utilizes a combination of screening to remove solids, equalization tanks to balance flow and concentration, and oil & grease removal units to ensure that heavy fats do not interfere with further treatment stages or equipment.Q: When should the automatic sludge dewatering system be utilized?

A: The automatic sludge dewatering system operates based on predefined sludge build-up levels within the plant. It can be programmed to cycle at intervals suitable to the plants capacity and sludge generation rates, ensuring efficient and hands-free sludge management.Q: Where can this plant be installed, and how flexible is its placement?

A: The system can be installed at slaughterhouses, abattoirs, and meat processing units. Its skid-mounted, modular design and customizable dimensions support flexible placement in facilities with space constraints or unique site layouts.Q: What benefits does PLC-based automation bring to plant operation?

A: PLC-based automation minimizes manual intervention, reduces the risk of operational errors, enables detailed monitoring, and allows for automatic adjustments, thereby improving plant efficiency, safety, and compliance.Q: How does the plant ensure compliance with CPCB discharge norms?

A: By combining advanced pretreatment, membrane filtration (0.1 micron), and automated controls, the plant consistently treats wastewater to meet or exceed CPCB standards for final effluent discharge.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wastewater Treatment Plants' category

"We are mainly dealing our products in North India"

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free